Coil Slitting Machine: Revolutionizing the Metal Processing Industry

2025-04-11

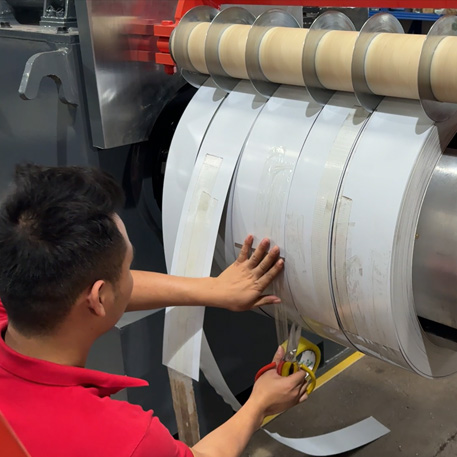

In the world of metal processing, precision and efficiency are paramount. Whether for manufacturing, packaging, or construction, metal coils need to be cut into narrower widths to meet specific requirements. This is where a coil slitting machine becomes essential. This versatile piece of equipment is designed to slit wide coils of metal into precise, narrower strips with high accuracy and speed.

What is a Coil Slitting Machine?

A coil slitting machine is a machine tool used in the metalworking industry to cut wide coils of metal into narrower strips. These coils are often made of materials such as steel, aluminum, copper, or other metals. The machine operates by passing the coil through a set of rotating circular blades, which slice the material into multiple narrow widths according to preset specifications.

The process involves unwinding the metal coil, feeding it through the slitting heads, and then recoiling the resulting strips. Coil slitting machines are used in a wide variety of industries, including automotive, construction, manufacturing, and packaging, where precise metal strips are required for various applications.

Why is the Coil Slitting Machine Important?

1. Precision Cutting: One of the key benefits of a coil slitting machine is its ability to produce narrow strips with high precision. The machine's cutting heads can be adjusted to ensure that the strips are cut to the exact required width. This level of accuracy is vital in industries where even the smallest deviation can lead to significant issues in the manufacturing process.

2. Efficiency and Speed: The coil slitting machine is designed to cut large volumes of metal in a short period. Unlike manual cutting methods, which are time-consuming and prone to errors, the slitting machine can process coils continuously, improving productivity. This efficiency helps manufacturers meet tight deadlines and large-scale production demands.

3. Versatility: Coil slitting machines are highly adaptable to different materials and thicknesses. They can be used for slitting a variety of metals, including mild steel, stainless steel, aluminum, and copper. This versatility makes them valuable tools in industries that require a wide range of materials to be cut to specific dimensions.

4. Cost-Effectiveness: By automating the slitting process, coil slitting machines significantly reduce labor costs and material wastage. The precision of the cuts ensures that the maximum amount of usable material is produced, minimizing scrap and reducing overall production costs. This makes the coil slitting machine a cost-effective solution for manufacturers.

Key Components of a Coil Slitting Machine

1. Unwinding Section: The unwinding section is where the large coil of metal is loaded onto the machine. This part of the machine ensures that the coil is properly unwound and prepared for the slitting process.

2. Slitting Heads: The slitting heads are the primary cutting mechanism of the machine. These circular blades are mounted on shafts and rotate at high speeds to slice the metal coil into narrower strips. The number of slitting heads can vary depending on the machine’s design and the desired number of strips.

3. Recoiling Section: After the metal has been slit, it is then rewound into coils in the recoiling section. This section gathers the individual strips into compact coils, which are then ready for further processing or shipping.

4. Drive and Control Systems: The drive system powers the movement of the metal coil through the slitting machine, while the control system ensures that the slitting process is carried out accurately. Modern coil slitting machines are equipped with advanced automation and control features, such as programmable logic controllers (PLCs), to improve precision and reduce human error.

Types of Coil Slitting Machines

1. Double Slitting Machines: These machines are equipped with two slitting heads and are ideal for processing narrow coils. They are typically used for high-speed, high-precision cutting tasks where two narrower strips are required from a single coil.

2. Slitting and Recoiling Machines: These are more advanced machines that can handle both the slitting and recoiling operations. They allow for continuous, automated processing, making them highly efficient for high-volume production.

3. Turret Slitting Machines: Turret slitting machines use a rotating turret system that holds multiple slitting blades. The turret rotates to select the desired blade for each slitting operation. This setup is ideal for machines that need to handle a variety of slitting configurations.

4. Heavy-Duty Slitting Machines: These machines are designed for thick, heavy-gauge coils. They are built with more robust components to handle high-strength materials and provide precise cutting without compromising on quality or speed.

Applications of Coil Slitting Machines

1. Automotive Industry: The automotive industry uses coil slitting machines to create metal strips that are used in the manufacturing of vehicle parts such as body panels, exhaust systems, and engine components. The precision and speed of the slitting machine are crucial to meet the high demands of automotive production.

2. Construction and Manufacturing: Metal strips produced by coil slitting machines are often used in construction and manufacturing applications, including the creation of roofing materials, metal panels, and structural components.

3. Packaging: Coil slitting machines are also used in the packaging industry to create metal strips that are used for wrapping and securing products. These strips are used for packaging heavy goods, such as pallets, crates, and machinery.

4. Electrical Industry: In the electrical industry, metal strips are needed for the production of electrical wiring, connectors, and components. Coil slitting machines provide the precision and quality required for these sensitive applications.

Tips for Maintaining Coil Slitting Machines

1. Regular Inspection: To ensure that the machine operates efficiently, it is important to regularly inspect the blades, shafts, and control systems. This will help identify any wear or malfunction before it impacts the production process.

2. Lubrication: Proper lubrication of the moving parts of the machine is essential for smooth operation and to prevent excessive wear. Regularly oiling the slitting heads and other components will extend the life of the machine.

3. Blade Maintenance: The blades used in the slitting machine should be regularly sharpened or replaced to maintain cutting efficiency. Dull blades can cause inaccurate cuts and increase the likelihood of material wastage.

4. Training Operators: Ensuring that operators are properly trained is critical to the success of any slitting operation. Well-trained operators can troubleshoot issues quickly and ensure the machine is running at optimal performance.

Conclusion

The coil slitting machine plays an integral role in modern metal processing. Its ability to cut wide coils into narrow strips with precision and efficiency makes it an invaluable tool in a wide range of industries. Whether for automotive manufacturing, construction, or packaging, coil slitting machines offer cost-effective, high-quality solutions to meet production demands. With proper maintenance and regular inspection, these machines can provide reliable performance for many years, ensuring that manufacturers can meet their goals while maintaining high standards of quality.