Design and Operation of Swing Check Valve

2024-07-12

A swing check valve is a type of check valve used in piping systems to allow fluid flow in one direction only and prevent backflow. Here are the key aspects and functionalities of swing check valves:

Design and Operation

1. Valve Mechanism

- Swing Disc: The valve has a hinged disc (flapper) that swings on a hinge or pivot mechanism.

- Flow Direction: Allows fluid to flow freely in one direction (forward flow) by swinging the disc open when fluid pressure exceeds the cracking pressure.

- Closure: When fluid flow stops or reverses, the disc swings back to its closed position due to gravity or a spring, blocking reverse flow.

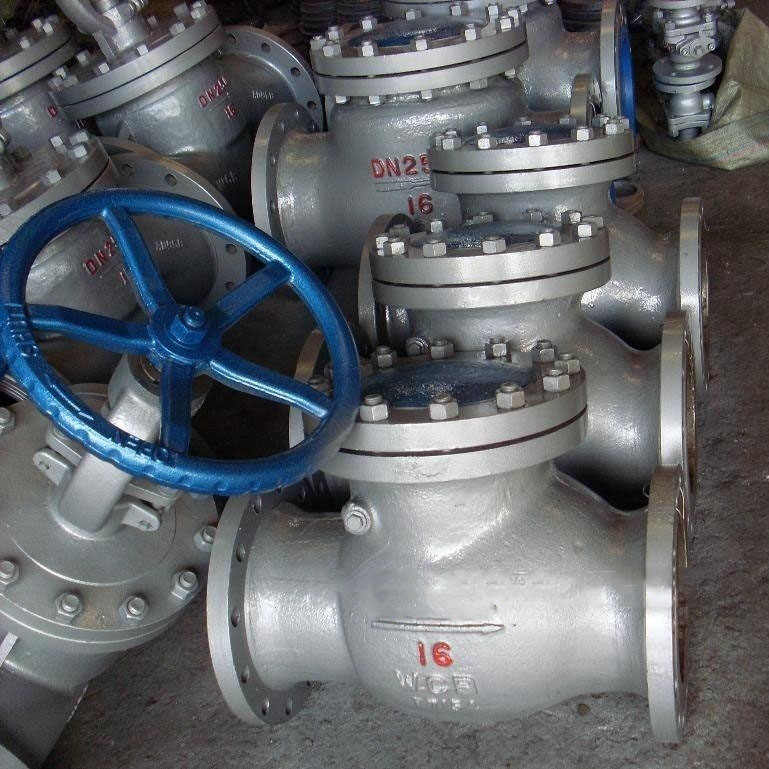

2. Body Design

- Body Configuration: Typically designed with a horizontal pipe and the disc positioned perpendicular to the flow direction.

- Materials: Constructed from various materials such as cast iron, ductile iron, stainless steel, bronze, or PVC, depending on the application's pressure and temperature requirements.

Applications

1. Water Systems

- Municipal Water Supply: Used in water distribution systems to prevent backflow and maintain water pressure.

- Wastewater Systems: Ensures proper flow direction and prevents sewage or effluent from backing up into pipes.

2. Industrial Applications

- Process Pipelines: Used in industrial facilities to control fluid flow and prevent damage from backflow.

- Chemical Processing: Installed in pipelines handling chemicals to prevent contamination or damage to equipment.

3. HVAC Systems

- Heating and Cooling Systems: Used in HVAC (Heating, Ventilation, and Air Conditioning) systems to control water flow and prevent reverse flow that could affect system efficiency.

Features and Benefits

1. Reliability

- Effective Sealing: Provides tight shut-off to prevent leakage and ensure efficient operation.

- Low Maintenance: Simple design with few moving parts reduces maintenance requirements and potential failure points.

2. Versatility

- Size Range: Available in various sizes to accommodate different pipe diameters and flow rates.

- Pressure Ratings: Designed to withstand high pressures and temperatures, depending on the material and configuration.

Considerations

- Installation: Proper orientation (vertical or horizontal) and location are crucial for optimal performance.

- Maintenance: Regular inspection and cleaning may be necessary to ensure smooth operation and prevent debris from interfering with the disc movement.

- Application Specifics: Selecting the right material and size based on fluid type, pressure, temperature, and environmental conditions ensures longevity and reliability.

Summary

A swing check valve is a fundamental component in piping systems, providing essential backflow prevention and ensuring efficient fluid flow in various applications, from water distribution and wastewater management to industrial processes and HVAC systems. Understanding its design, operation, and application considerations helps in selecting and deploying swing check valves effectively to maintain system integrity and reliability.