Features and applications of metal mesh belts

2023-12-01

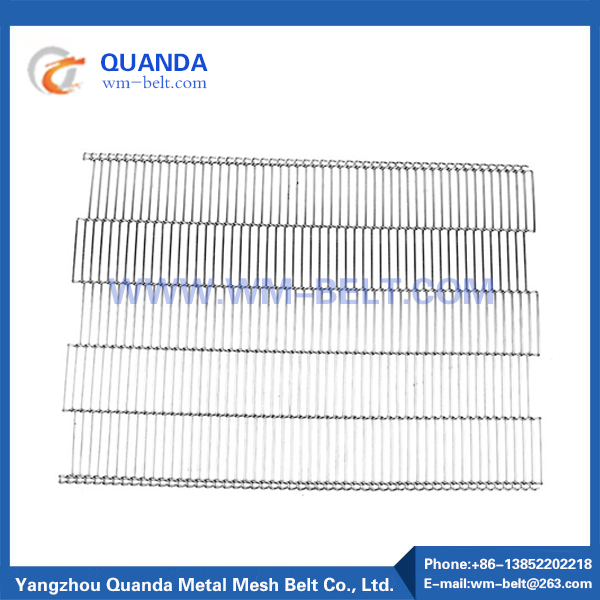

A metal mesh belt, also known as a wire mesh conveyor belt or simply a mesh belt, is a type of conveyor belt made from interlinked metal wires. These belts are commonly used in industrial applications for conveying, heat treating, drying, cooling, and various other processes. The construction of metal mesh belts allows for efficient heat transfer, airflow, and drainage, making them suitable for diverse manufacturing and processing operations. Here are some key features and applications of metal mesh belts:

Features:

1. Material Composition:

- Metal mesh belts are typically made from stainless steel or other alloys, offering durability, corrosion resistance, and high-temperature resistance.

2. Interlinked Design:

- The belt consists of interlinked wires, forming a continuous mesh. The interlocking design provides flexibility while maintaining strength.

3. Openings and Mesh Size:

- The belts can have various mesh sizes and openings, allowing for customization based on the specific application requirements, such as product size and airflow needs.

4. Flat or Balanced Weave:

- Metal mesh belts can be designed with a flat or balanced weave, depending on the application. Flat weaves provide a smooth surface, while balanced weaves offer better stability.

5. High Strength:

- The interlocking design and use of strong metals make metal mesh belts capable of handling heavy loads and withstanding harsh industrial conditions.

6. Temperature Resistance:

- Metal mesh belts are resistant to high temperatures, making them suitable for applications involving heat treatment, drying, and other thermal processes.

7. Chemical Resistance:

- Stainless steel or other alloy materials provide resistance to chemicals and corrosive substances, ensuring the durability of the mesh belt in various environments.

8. Easy Cleaning:

- The open structure of the mesh allows for easy cleaning and maintenance, making these belts suitable for industries where hygiene is crucial, such as food processing.

Applications:

1. Heat Treatment:

- Metal mesh belts are commonly used in heat treatment processes such as annealing, hardening, and quenching due to their high-temperature resistance.

2. Drying and Cooling:

- They are utilized in drying processes for products like textiles, paper, and certain food items. Additionally, they are employed in cooling applications where airflow is crucial.

3. Food Processing:

- Metal mesh belts are widely used in the food industry for baking, cooking, frying, and freezing applications. They facilitate even heat distribution and efficient airflow.

4. Automotive Industry:

- Metal mesh belts are employed in automotive manufacturing processes, including painting, coating, and curing applications.

5. Glass Production:

- In the glass industry, metal mesh belts are used for conveying glass sheets through various stages of production, such as tempering and annealing.

6. Electronics Manufacturing:

- Metal mesh belts play a role in conveying electronic components through processes like soldering and circuit board manufacturing.

7. Textile Industry:

- Textile drying and curing processes often involve the use of metal mesh belts due to their ability to handle high temperatures and provide efficient airflow.

8. Chemical Processing:

- Metal mesh belts are used in chemical processing plants where resistance to corrosive materials is essential.

Metal mesh belts are versatile and can be customized to meet specific application requirements. Their durability, high-temperature resistance, and efficient material handling capabilities make them valuable in a wide range of industrial processes.