Features of Aluminum Terminal Blocks

2024-07-15

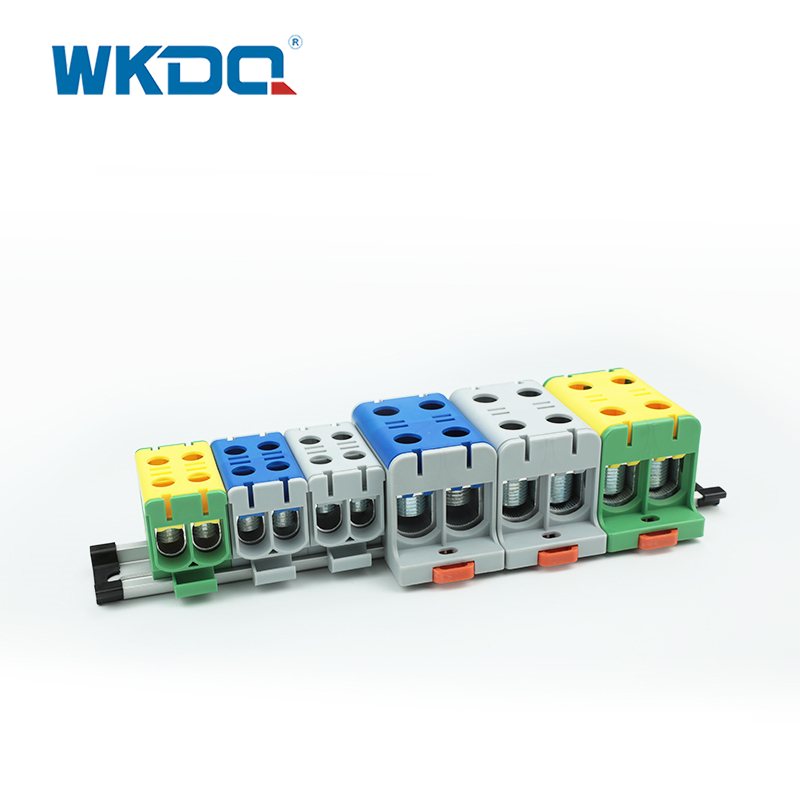

An aluminum terminal block is a type of electrical connector used to secure and terminate electrical wires or cables in various applications. These terminal blocks are specifically designed using aluminum for its conductivity, durability, and corrosion resistance. Here’s an overview of aluminum terminal blocks, their features, applications, and considerations:

Features of Aluminum Terminal Blocks

1. Material:

- Aluminum Alloy: Constructed from aluminum alloys known for their high electrical conductivity and mechanical strength.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, making these terminal blocks suitable for both indoor and outdoor applications.

2. Design:

- Terminal Configuration: Typically available in configurations such as screw-type, spring-clamp, or push-in terminals.

- Mounting Options: Designed for DIN rail mounting or direct panel mounting depending on the application requirements.

3. Electrical Properties:

- Conductivity: Aluminum provides good electrical conductivity, ensuring efficient transmission of electrical signals or power.

- Temperature Resistance: Capable of operating within a wide temperature range, suitable for various environmental conditions.

4. Versatility:

- Compatibility: Designed to accommodate a range of wire sizes and types (solid or stranded) depending on the terminal block design.

- Modularity: Some terminal blocks allow for modular assembly, enabling flexibility in configuring electrical connections.

5. Safety and Reliability:

- Insulation: Equipped with insulation materials to prevent accidental contact and ensure electrical safety.

- Longevity: Designed for durability and long-term reliability in industrial and commercial environments.

Applications of Aluminum Terminal Blocks

1. Electrical Panels and Cabinets:

- Power Distribution: Used for connecting and distributing electrical power within control panels, switchgear, and distribution boards.

- Signal Wiring: Suitable for terminating signal wires in control systems and automation equipment.

2. Industrial Machinery:

- Control Systems: Integral in wiring control circuits for motors, sensors, actuators, and other industrial equipment.

- Process Automation: Facilitates reliable connections in PLC (Programmable Logic Controller) systems and industrial automation networks.

3. Renewable Energy Systems:

- Solar PV Systems: Used in junction boxes and combiner boxes to connect solar panels and manage power output.

- Wind Turbines: Facilitates electrical connections in wind turbine control and power distribution systems.

4. Transportation and Automotive:

- Railway Systems: Used in railway signaling, control panels, and traction systems.

- Automotive Manufacturing: Used in vehicle electrical systems for connecting wiring harnesses and components.

5. Building Infrastructure:

- HVAC Systems: Used in HVAC control panels for connecting thermostats, actuators, and heating elements.

- Building Automation: Integral in wiring building management systems and HVAC controls.

Considerations for Selecting Aluminum Terminal Blocks

1. Current and Voltage Ratings:

- Match: Ensure terminal blocks meet or exceed the current and voltage requirements of the application to prevent overheating or electrical failures.

2. Environmental Conditions:

- IP Rating: Choose terminal blocks with appropriate IP (Ingress Protection) ratings for protection against dust, moisture, and environmental hazards.

- Temperature Range: Verify temperature ratings to ensure suitability for the operating environment (e.g., indoor, outdoor, hazardous areas).

3. Installation and Mounting:

- Mounting Type: Select terminal blocks compatible with DIN rail mounting or panel mounting based on installation preferences and space constraints.

- Ease of Wiring: Consider terminal blocks that facilitate easy wiring and maintenance, such as those with clear marking and accessible terminals.

4. Safety Standards:

- Compliance: Ensure terminal blocks comply with relevant international standards (e.g., IEC, UL) for electrical safety and performance.

5. Customization and Integration:

- Modularity: Opt for modular terminal blocks that allow for easy customization and expansion of electrical connections as needed.

- Compatibility: Verify compatibility with existing wiring systems and components to ensure seamless integration.

Leading Manufacturers and Models

1. Phoenix Contact: Offers a wide range of aluminum terminal blocks with various features for industrial and commercial applications.

2. WAGO: Provides innovative aluminum terminal blocks known for their reliability and ease of use in electrical installations.

3. ABB: Supplies robust terminal blocks suitable for demanding applications in industrial automation and power distribution.

4. Weidmüller: Known for high-quality aluminum terminal blocks designed for industrial control and automation systems.

5. Schneider Electric: Provides durable and efficient terminal blocks for electrical panel installations and industrial applications.

Conclusion

Aluminum terminal blocks play a critical role in electrical installations across various industries, providing secure and reliable connections for power distribution and control systems. By selecting the right terminal blocks based on electrical requirements, environmental conditions, and installation preferences, businesses can ensure efficient and safe operation of their electrical systems while maintaining compliance with industry standards.