Here are the key features and components of a typical metal chip briquetting machine

2023-12-08

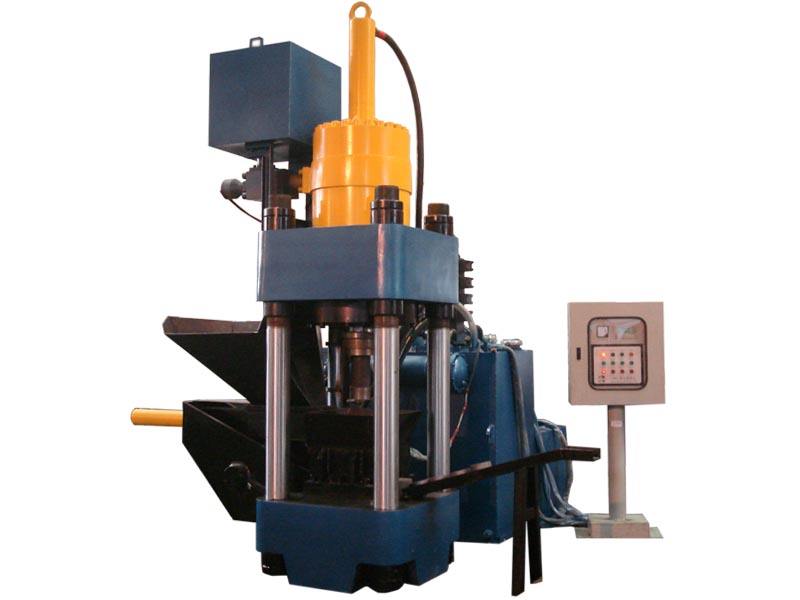

A metal chip briquetting machine is a specialized piece of equipment designed to compress metal chips or shavings into compact and manageable briquettes. This process is commonly used in metalworking and machining operations where metal chips are generated as a byproduct. The briquetting machine helps in recycling and reusing these metal chips by compressing them into briquettes, which can be more easily handled, transported, and recycled. Here are the key features and components of a typical metal chip briquetting machine:

1. Hopper or Bin: Metal chips are collected in a hopper or bin before being fed into the briquetting machine. The hopper ensures a consistent and controlled supply of metal chips.

2. Conveyor System: A conveyor system is often used to transport metal chips from the hopper to the briquetting machine. This helps automate the feeding process.

3. Briquetting Chamber: The briquetting chamber is where the metal chips are compressed into briquettes. It contains a compression mechanism that exerts pressure on the metal chips.

4. Hydraulic System: Like many industrial briquetting machines, a metal chip briquetting machine typically uses a hydraulic system to generate the force needed for compression. This system includes a hydraulic pump, cylinders, and valves.

5. Compression Ram or Piston: The hydraulic system powers a compression ram or piston that moves to compress the metal chips. The compression force results in the formation of briquettes.

6. Briquette Ejection Mechanism: Once the briquettes are formed, an ejection mechanism releases the briquettes from the machine. Some machines have automated systems for ejecting the briquettes.

7. Briquette Collecting System: A system for collecting and conveying the produced briquettes to a storage area or for further processing.

8. Control Panel: The control panel allows operators to set parameters such as compression force, briquette size, and other operating conditions. It may also include safety features and indicators.

9. Cooling System: Some metal chip briquetting machines incorporate a cooling system to manage heat generated during the compression process.

10. Briquette Size Adjustment: Some machines allow for the adjustment of briquette size to meet specific requirements.

Metal chip briquetting machines are used to process various types of metal chips, including aluminum, brass, copper, steel, and other alloys. The resulting briquettes can be recycled in metal smelting processes or sold to recycling facilities. This not only helps in waste reduction but also contributes to environmental sustainability by promoting the efficient use of metal resources.