Key points about ring type special-shaped forgings

2023-10-20

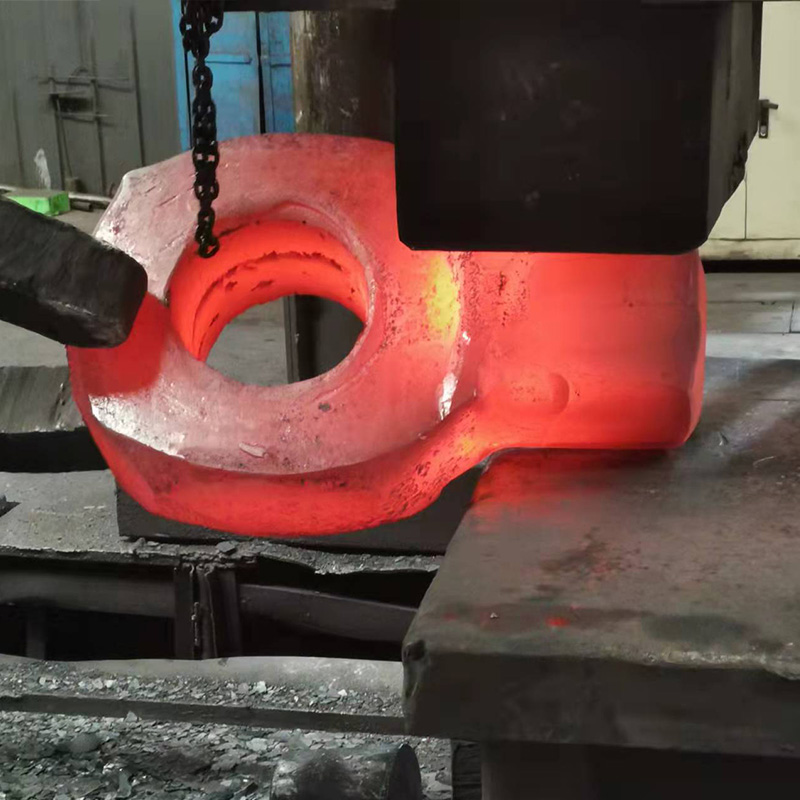

Forgings are metal components manufactured through a forging process, which involves heating the metal to a high temperature and then shaping it using mechanical force. In the case of ring type special-shaped forgings, the end product takes on the form of a ring but may have specific contours, features, or profiles that deviate from the traditional circular ring shape. Here are some key points about ring type special-shaped forgings:

1. Unique Shapes: Unlike standard circular rings, ring type special-shaped forgings are designed with non-standard or custom shapes. These shapes can vary widely based on the intended application and specific requirements of the component.

2. Forging Process: The manufacturing process involves heating the metal to a malleable state and then using specialized dies and presses to shape the material into the desired form. This process ensures the forged components have enhanced mechanical properties, including strength and durability.

3. Applications: These special-shaped forgings are used in a variety of industries and applications. Their unique shapes are often tailored to fit specific machinery, equipment, or structural requirements. They can serve as connectors, supports, or load-bearing components.

4. Materials: Ring type special-shaped forgings can be made from a wide range of metals and alloys, including carbon steel, stainless steel, aluminum, brass, and exotic alloys, depending on the performance characteristics required for the application.

5. Customization: Manufacturers can produce ring type special-shaped forgings to meet the exact specifications and design criteria provided by customers. This includes considerations such as size, shape, material, and tolerance requirements.

6. Quality and Testing: To ensure the quality and integrity of these forgings, they may undergo rigorous testing and quality control processes, including non-destructive testing (NDT) methods like ultrasonic testing, magnetic particle inspection, and others.

7. Precision Machining: After the forging process, some components may require additional machining or finishing operations to achieve precise dimensions, surface finishes, or threaded features.

8. Diverse Industries: Ring type special-shaped forgings are utilized in industries such as aerospace, automotive, oil and gas, power generation, and heavy machinery, among others.

In summary, ring type special-shaped forgings are forged components with unique ring-like shapes that deviate from the standard circular ring form. They are used in various industrial applications where custom-shaped components are needed to meet specific design and performance requirements. These forgings are valued for their strength, durability, and ability to withstand demanding operating conditions.