Understanding Printer Ribbons: Types, Uses, and Best Practices

2024-10-09

In an increasingly digital world, printing may seem like a relic of the past. However, printing remains essential in many industries, and printer ribbons are critical in this process. Whether for label printers, dot matrix printers, or older technology, understanding printer ribbons, their types, uses, and maintenance can help you achieve the best results. In this blog post, we will explore everything you need to know about printer ribbons.

What is a Printer Ribbon?

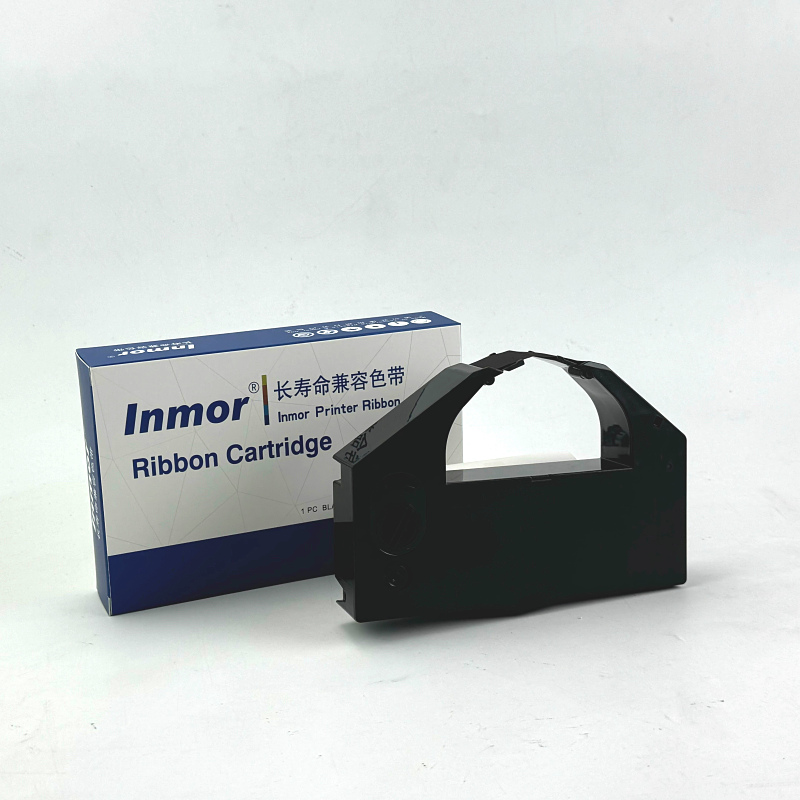

A printer ribbon is a consumable component used in certain types of printers to transfer ink onto paper. It consists of a long strip of fabric or plastic coated with ink, which moves back and forth during the printing process. Printer ribbons are commonly used in dot matrix printers, impact printers, and thermal transfer printers.

Types of Printer Ribbons

1. Fabric Ribbons

Fabric ribbons are commonly used in dot matrix printers. These ribbons are made from a woven fabric material and are saturated with ink. As the printer head strikes the ribbon, it transfers ink onto the paper. Fabric ribbons are known for their durability and cost-effectiveness, making them suitable for high-volume printing tasks. They are often used in environments where printed documents need to withstand wear and tear, such as warehouses or shipping departments.

2. Thermal Ribbons

Thermal ribbons are primarily used in thermal transfer printers. These ribbons are coated with a special wax, resin, or a combination of both. During the printing process, heat is applied to the ribbon, causing the ink to transfer onto the printing surface. Thermal ribbons produce high-quality, smudge-proof prints and are commonly used for barcode labels, shipping labels, and product tags.

3. Ink Ribbons

Ink ribbons are often used in older impact printers and typewriters. These ribbons consist of a plastic or fabric strip coated with a thick layer of ink. They provide a more traditional printing method and can be used for various applications, including printing invoices, receipts, and reports. Ink ribbons tend to have a shorter lifespan than fabric or thermal ribbons and may need to be replaced more frequently.

4. Dye-Sublimation Ribbons

Dye-sublimation ribbons are used in dye-sublimation printers, which are commonly employed for high-quality photo printing. These ribbons consist of multiple panels of dye, which are heated and transferred onto the printing surface. Dye-sublimation printing produces vibrant colors and smooth gradients, making it ideal for producing photographs, ID cards, and specialty items.

Uses of Printer Ribbons

Printer ribbons have various applications across different industries:

- Label Printing: Ribbons are essential for printing labels, including shipping labels, barcodes, and product labels. They ensure clear, durable prints that can withstand handling and environmental conditions.

- Receipt Printing: Many point-of-sale systems still use thermal printers and ribbons to print receipts, providing customers with a tangible record of their transactions.

- Office Printing: Businesses that rely on dot matrix printers for bulk printing tasks, such as invoices and reports, use fabric ribbons for efficiency and cost-effectiveness.

- Photo Printing: Dye-sublimation ribbons are widely used in photography studios and for producing high-quality prints for events like weddings and graduations.

Best Practices for Using Printer Ribbons

To ensure optimal performance and longevity of printer ribbons, follow these best practices:

1. Choose the Right Ribbon for Your Printer

Different printers require specific types of ribbons. Always refer to your printer’s user manual to determine the compatible ribbon type, whether fabric, thermal, ink, or dye-sublimation.

2. Store Ribbons Properly

Printer ribbons should be stored in a cool, dry place, away from direct sunlight. High temperatures and humidity can affect the ink's quality and lead to poor print results.

3. Monitor Ribbon Usage

Keep track of ribbon usage, especially in high-volume printing environments. Most printers provide a way to monitor the remaining ink levels in the ribbon, allowing you to plan for replacements and minimize downtime.

4. Clean Your Printer Regularly

Dust and debris can accumulate in printers, affecting print quality and ribbon performance. Regularly clean the printer heads and surrounding areas to ensure smooth operation and prolong the life of your ribbons.

5. Replace Ribbons When Necessary

If you notice faded prints, streaks, or other quality issues, it may be time to replace the ribbon. Ignoring these signs can lead to more significant problems down the line.

Conclusion

While digital solutions dominate the modern landscape, printer ribbons remain vital for many businesses and industries. Understanding the types, uses, and maintenance of printer ribbons can enhance your printing experience and ensure high-quality results. Whether you're printing labels, receipts, or photographs, the right ribbon will significantly impact your output. By following best practices for ribbon selection and maintenance, you can maximize efficiency and achieve excellent print quality every time. So, the next time you reach for that printer, remember the essential role that ribbons play in bringing your printed documents to life!