What Is CNC Machining and Why Is It Vital in Modern Manufacturing?

2025-06-24

CNC machining stands for Computer Numerical Control machining—a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. This technology enables precise and automated production of complex parts and components with minimal human intervention, making it a cornerstone of modern manufacturing.

What Is CNC Machining?

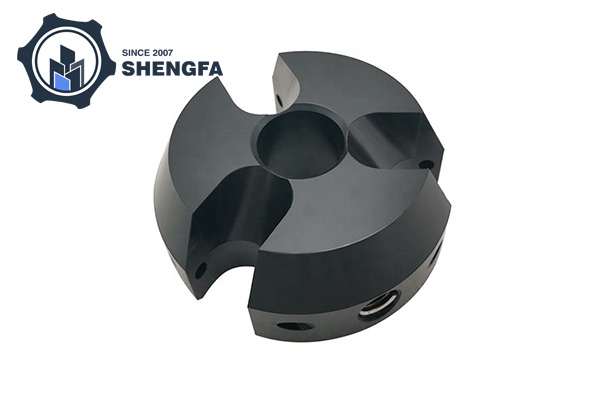

CNC machining uses computerized controls to operate tools such as lathes, mills, routers, and grinders. The process starts with designing a part using CAD (Computer-Aided Design) software, which is then translated into G-code—a language that directs the CNC machine’s actions. The machine executes the program to cut, drill, shape, or finish the material with high accuracy.

Key Features and Benefits

Precision and Accuracy: CNC machines can produce parts with tight tolerances and repeatability.

Automation: Reduces manual labor and human error.

Flexibility: Can quickly switch between different designs and materials.

Complex Geometry: Capable of producing intricate shapes that would be difficult or impossible manually.

Efficiency: Speeds up production and lowers waste.

Consistency: Every part made is virtually identical, crucial for quality control.

Common Materials Used in CNC Machining

Metals: Aluminum, steel, brass, titanium, copper.

Plastics: Acrylic, nylon, polycarbonate.

Composites and wood.

Applications of CNC Machining

Automotive: Engine parts, gearboxes, and custom components.

Aerospace: Precision components for aircraft and spacecraft.

Medical Devices: Surgical instruments and implants.

Electronics: Housings and heat sinks.

Consumer Products: Custom parts for gadgets and appliances.

Types of CNC Machines

CNC Milling Machines: Use rotary cutters to remove material.

CNC Lathes: Rotate the workpiece to perform cutting.

CNC Routers: Ideal for wood, plastic, and soft metals.

EDM (Electrical Discharge Machines): Use electrical discharges to shape hard materials.

Conclusion

CNC machining is a transformative technology in manufacturing, enabling high precision, flexibility, and efficiency. Its ability to produce complex parts consistently makes it invaluable across diverse industries, from aerospace to consumer electronics.