Why Are Duplex Steel Flanges the Preferred Choice for High-Performance Piping Systems?

2024-12-26

When it comes to building robust and high-performance piping systems, choosing the right material is crucial. Duplex steel flanges have emerged as one of the most sought-after components in industries that demand superior strength, corrosion resistance, and reliability. But what makes duplex steel flanges stand out from the rest? Let’s dive into the reasons why these flanges are the go-to solution for modern piping applications.

What Are Duplex Steel Flanges?

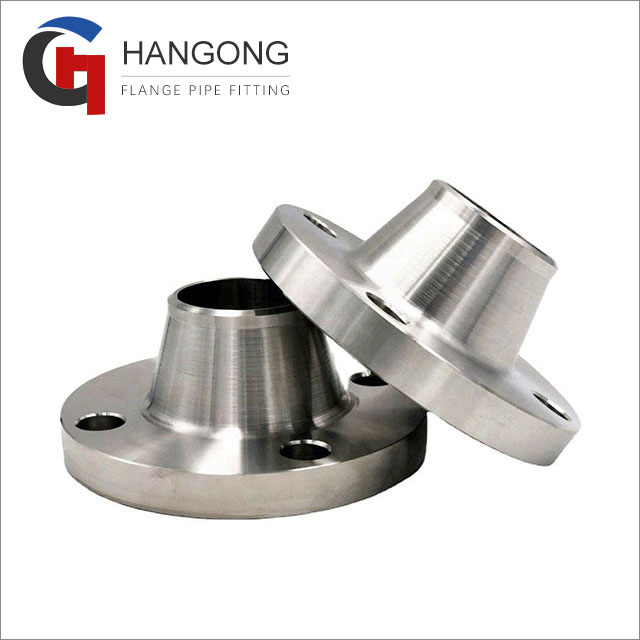

Duplex steel flanges are made from a type of stainless steel that combines both austenitic and ferritic steel, resulting in a material that offers the best of both worlds. The duplex structure provides enhanced strength and better resistance to corrosion compared to regular stainless steel.

These flanges are designed to join pipes, valves, pumps, and other equipment in a system, ensuring a leak-proof and durable connection. Their unique composition makes them ideal for challenging environments, including those exposed to high pressure, temperature, and corrosive substances.

Why Are Duplex Steel Flanges So Popular?

1. Superior Corrosion Resistance

Duplex steel flanges are highly resistant to a wide range of corrosive environments, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for industries like oil and gas, chemical processing, and marine applications where exposure to harsh chemicals and saltwater is common.

2. Exceptional Strength

The duplex microstructure enhances the strength of the material, making duplex steel flanges stronger than regular stainless steel flanges. This allows them to handle high-pressure systems and extreme mechanical stresses without failure.

3. Improved Fatigue and Thermal Resistance

Duplex steel flanges can withstand higher temperatures and offer better fatigue resistance than other types of steel. This makes them suitable for applications with fluctuating temperatures or cyclic loading.

4. Cost-Effective Solution

While duplex steel flanges may have a higher upfront cost compared to regular stainless steel, their superior performance and durability lead to long-term savings. They require less maintenance and have a longer service life, reducing the overall cost of ownership.

5. Good Weldability

Duplex steel flanges are easy to weld, making them a versatile option for various piping configurations. They maintain their strength and resistance even after being welded, ensuring a secure and reliable connection.

Where Are Duplex Steel Flanges Used?

1. Oil and Gas Industry

- Offshore platforms

- High-pressure pipelines

- Subsea systems

2. Chemical and Petrochemical Plants

- Handling corrosive chemicals and acids

- High-temperature reactors and heat exchangers

3. Marine and Offshore Applications

- Saltwater exposure in pipelines and equipment

- Desalination plants

4. Water Treatment Facilities

- Sewage systems and desalination processes

- Chemical dosing systems

5. Power Generation

- High-pressure steam systems

- Cooling towers and heat exchangers

What Makes Duplex Steel Flanges Stand Out from Other Materials?

1. Combination of Strength and Corrosion Resistance

Duplex steel flanges offer superior mechanical strength and corrosion resistance compared to traditional austenitic stainless steel and carbon steel. This balance makes them ideal for extreme conditions where both factors are critical.

2. Resistance to Chloride Stress Corrosion Cracking

One of the standout features of duplex steel is its resistance to chloride stress corrosion cracking, a common issue in seawater or chemical environments. This is particularly valuable in offshore and marine industries.

3. Optimized for Harsh Environments

Whether in high-temperature systems or aggressive chemical processes, duplex steel flanges stand out for their ability to maintain structural integrity in tough conditions.

How to Choose the Right Duplex Steel Flange?

1. Material Grade

Duplex steel flanges are available in different grades, such as 2205 and 2507, with 2205 being the most common for general applications and 2507 providing higher strength and corrosion resistance for more demanding conditions.

2. Size and Pressure Rating

Make sure the flange size matches the pipe diameter and pressure requirements of your system. Duplex flanges are available in various pressure classes (e.g., ANSI, DIN).

3. Flange Type

The type of flange you choose depends on your system’s design, whether it’s a weld neck, blind, slip-on, or socket weld flange.

4. Environmental Conditions

Consider the specific environment where the flange will be used. Duplex steel is ideal for environments exposed to chloride or acidic conditions, as well as high temperatures.

Are Duplex Steel Flanges Worth the Investment?

Given their outstanding combination of strength, corrosion resistance, and durability, duplex steel flanges are undoubtedly a worthwhile investment. Whether you are involved in the oil and gas, marine, or chemical industry, choosing duplex steel flanges ensures the long-term reliability of your piping systems while reducing maintenance costs.

Conclusion

Duplex steel flanges offer a superior solution for demanding applications that require both strength and corrosion resistance. Their versatility across industries, combined with their cost-effectiveness and enhanced performance, makes them the material of choice for high-performance piping systems.